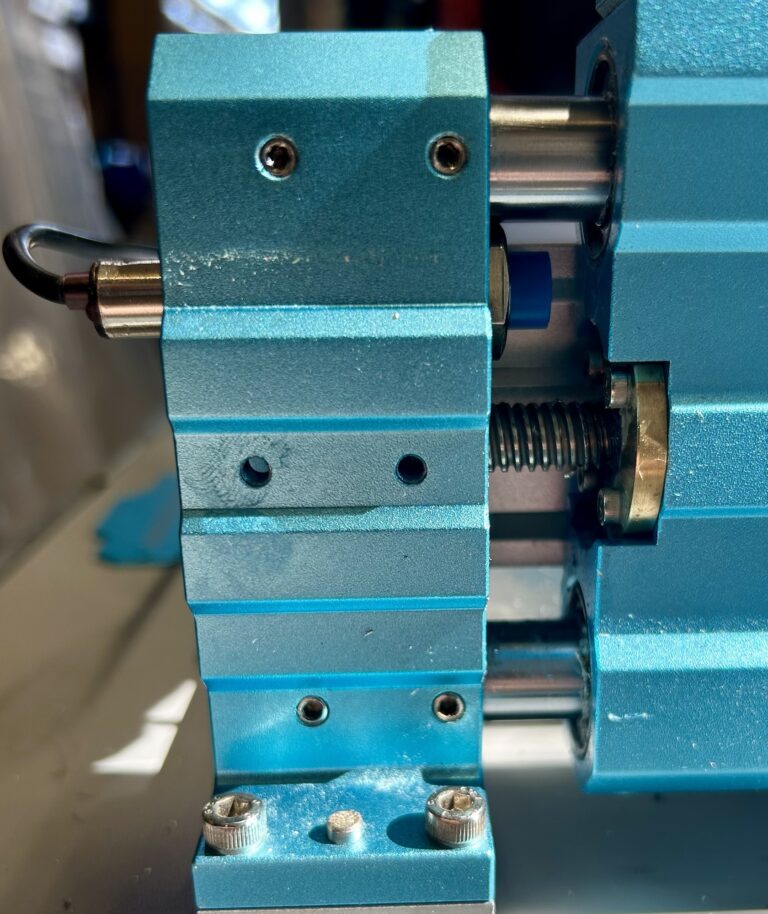

A-Axis on FluidDial

A-Axis rotary table support for FluidDial on PiBot CNC Pendant.

CNC Router modifications.

A-Axis rotary table support for FluidDial on PiBot CNC Pendant.

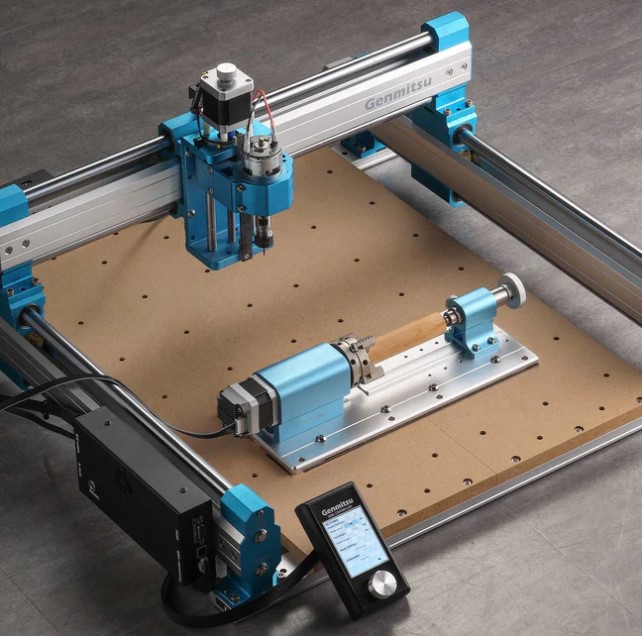

4th axis with FluidNC, PiBot, and a Genmitsu 4040 Pro Max CNC Router.

Using trash bags to protect my CNC Router rails and leadscrews from debris after spending hundreds of dollars trying to fit accordion style machine protection.

Easily add proximity sensors to the front (+) end of each of the Y axes on a SainSmart Genmitsu 4040 Pro Max CNC Router.

Finally upgraded the trim router spindle on my Genmitsu 4040 Pro Max with a 1.5KW air cooled VFD Spindle.

The case I used for the FluidNC CNC Controller based upgrade for my CNC Router. See the BOM for details. CAD for the case panels and other project files are located on the company github. All the panels are power coated steel, not aluminum. The white colored frame on the front and back is plastic….

What started out as a simple temperature and voltage monitoring device for my new CNC controller case ended up way more complex.

I discovered that the factory Genmitsu controller runs GRBL 1.1 that is only able to support 3 axes and isn’t upgradable to any other controller firmware.

A few weeks after ordering and not seeing the status on the SainSmart web site change to shipped, I sent an email to check on it. And that’s when the black hole of never ending time and money sucking began.